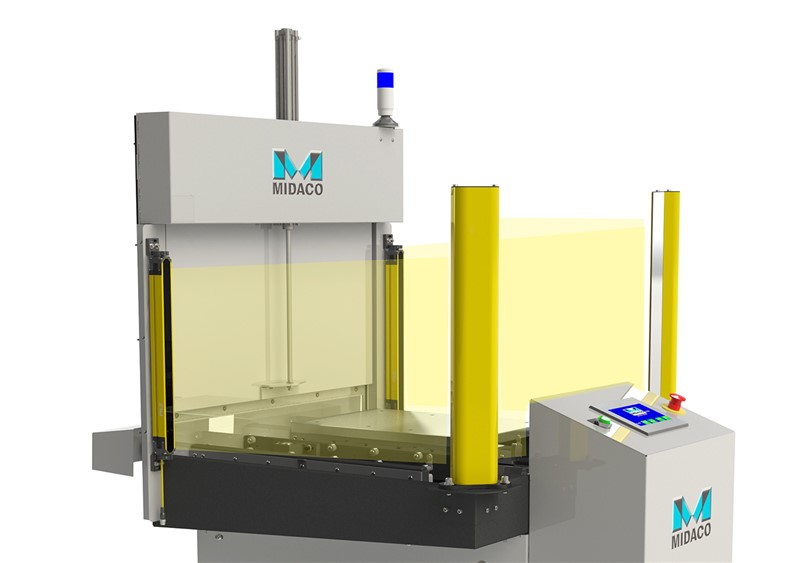

DUAL Automatic CE Pallet Changer specifically for the HAAS DM and DT series VMC.

Maximize walk-away time with a DUAL Shuttle Pallet Changer on your HAAS DM or DT Vertical Machining Center. Load up to 4 pallets - 2 on each side - and run parts unattended. Combining your VMC with a MIDACO Automatic Pallet Changer will deliver increased productivity and labor savings.

- Pallet Change time in only seconds: 6.5 on DT-1 & DM-1; 8 seconds on DT-2 & DM-2 (pallet change time may vary depending on weight of parts on pallet).

- Repeatability of +/- 0.0001" (0.0025mm)

- Pallet Changer is fully integrated with the machine control via 2 M-Functions

- Pneumatic receiver with 500 lb (227 kg) weight capacity.

- 2 shuttles (4 pallets): one mounted on either side of the machine for greater walk-away time.

All models of the Automatic Pallet Changer System are available with a Light Curtain package. With 3-sided guarding via a light emitter, mirrors and sensors, a pallet change will not occur if the invisible light beams surrounding the shuttle system are breached.