How long is your spindle idle while changing parts on a Bridge Mill?

...one hour ...two hours?

We can get it running in MINUTES!

In recent years we’ve expanded our line of pallet changers to accommodate the need for large precision parts machined to tight tolerances for the aerospace, energy, automotive, military, power generation, oil and gas industries. These jobs cause significant spindle downtime due to the long and involved process of heavy, large part change over. When combined with crane loading, first article inspection and job interruption tasks, the machining center can be idle for 30 minutes... an hour... two hours? Your large Vertical Bridge Mill or Double Column Machining Center can be idle up to 70% of the time.

Idle machine time means slow production and lost profit per each machine owned. MIDACO pallet changers are a simple solution to eliminate unnecessary spindle downtime and rescue lost profit on large as well as small and mid-size machining centers. A pallet changer allows you to load your part onto a shuttle outside the machine tool WHILE your VMC is cutting, then change out your large part in MINUTES.

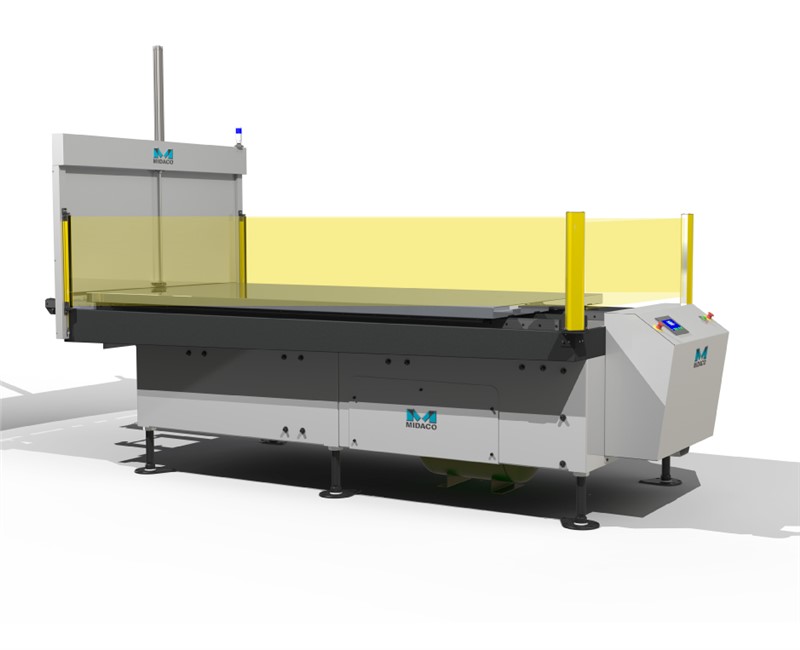

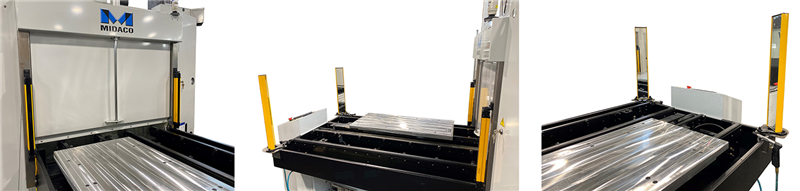

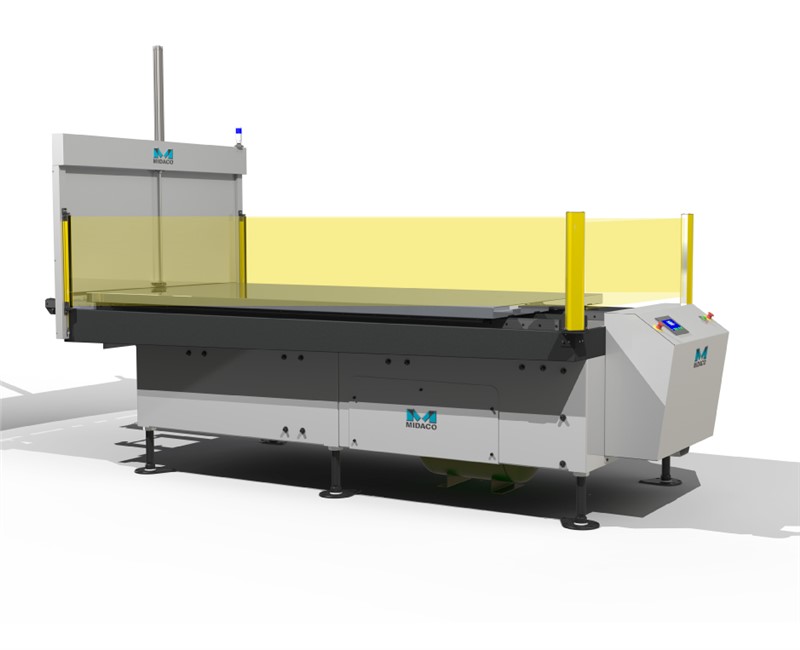

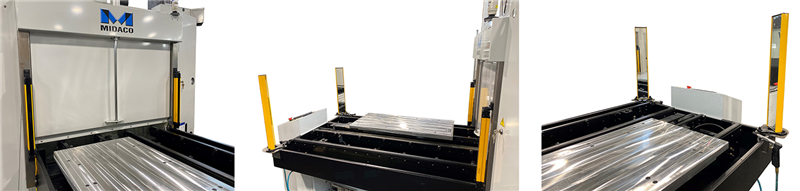

MIDACO manufactures pallet changers which adapt to virtually ANY brand and model machining center, including large bridge mills, with travels up to 190” x 72” (4826mm x 1829mm) and with a weight capacity of up to 32,000 lbs (14,528 kg). Automatic Pallet Systems are easily installed on the right side or the left side of a VMC, or both sides for machines which do not move in Y-Axis. Once a pallet or load of parts is complete, the next pallet or job is transferred into the machine automatically from our side mounted shuttle onto the receiver mounted to the VMC table. Because all part loading and job set-up tasks are performed offline (without the operator having to lean into or climb onto the machine) both productivity and ergonomics is maximized.

Optional Light CurtainAll models of the Automatic Pallet Changer System are available with a Light Curtain package. With 3-sided guarding via a light emitter, mirrors and sensors, a pallet change will not occur if the invisible light beams surrounding the shuttle system are breached.

Automatic Pallet Changers are servo driven and are designed to offer a fast pallet change time along with these additional benefits:

- Decrease in load time by changing parts outside of the machine tool.

- No overhead obstructions for your crane access.

- Operator is not leaning into or climbing around inside a machine tool to clamp and fixture parts on the VMC table.

- With multiple dedicated pallets you have additional set-ups available for your diverse machining needs.

- Don't allow your machine to sit idle up to 70% of the time. Keep the spindle running!