"Add to Cart" Direct Buy is available for the 48 contiguous United States. For orders outside of the 48 contiguous United States, send request via "Add Quote" above or contact MIDACO Sales at sales@midaco-corp.com

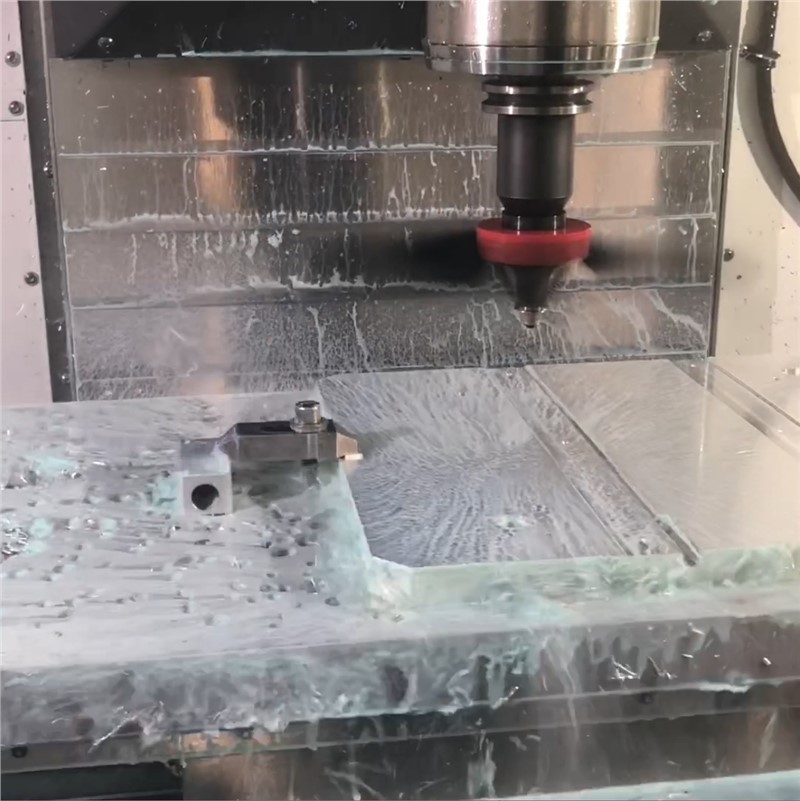

More than just a basic Chip Fan, our innovative line of Midaco cleaning fans for machine tools is a powerful addition to complement any CNC machine and eliminate the need to halt production for machine clearing and cleaning tasks. Built to last with durable, U.S. 4140 steel and glass fiber reinforced nylon, chip fan tools are a faster, safer alternative to other chip clearing mechanisms.

Superior Chip Fan and Coolant Cleaning Products from Midaco

Coolant clearing doesn’t need to pause production with the Midaco Fan. Ongoing or timed blowers use the power of air to direct coolant away based on programmed automation – saving time in enclosed machine centers.

- Shank with weldon flat: U.S. 4140 steel, 0.75" (19.05mm) dia.

- Dia. w/ Closed Blades: 2.7" (68.58mm)

- Through Coolant Ready

2 Sizes Available:

- Blade Length: 2.5" (63.5mm)

- Dia. w/ Open Blades: 6.3" (160mm)

- Operating Speed: 6,000 to 12,000 RPM

- Blade Length: 4.5" (114mm)

- Dia. w/ Open Blades: 10" (254mm)

- Operating Speed: 5,000 to 8,000 RPM

To be used in ENCLOSED machine ONLY!

Faster, More Streamlined Production with a CNC Chip Fan

Midaco Fan products eliminate the need to pause production for maintenance. Other essential benefits of chip fan for CNC products include:

- Safer production and less risk of injury to personnel

- High-speed coolant cleaning fan

- Easy Integration into CNC Machinery for Complete Automation

- Long-Term, Durable Investment as a High-Quality Machine Tool Chip Fan

- Smooth, Low-Volume Functionality for a Quieter Work Environment

Mount the Midaco Fan into your tool holder of choice and create length offset as needed. Be sure tool holder is rated for proper RPM. Based on your geometry, program the Midaco Fan similar to that of a face mill.

Upgrade with a Through Coolant Nozzle

Expand your through-spindle coolant and air-blower projection area. Reduce cleaning cycle time by decreasing the number of clean-up passes on the table. Ideal for larger beds, provides an 8” circumference of coverage. Available in 2.5” or 4.5” length.

Easy Part Replacement

The Midaco CNC Chip Fan is designed with an easy disassembly feature allowing quick replacement of parts.

- Replacement blades come with spring holding pins and positioning pins preassembled (available in single-blade and 4-blade kits).

- 4-Spring Replacement Kit includes 4 springs, 1 hook washer and 1 step washer.

- Fan Body Replacement Kit includes 1 black nose hub and 1 red base hub.

Midaco Fans: Our CNC Chip Blowers and Coolant Cleaning Fans

Since 1969, Midaco has been a leading manufacturer of pallet changers, automatic door systems, robot access doors, trunnion systems and other high-quality products, such as chip removal fan tools, designed for more efficiency in the workplace. Our mission is to provide our global customers with the world’s best and most innovative technologies—with state-of-the-art products that increase productivity, improve safety standards, lower costs, and enhance profits.