MIDACO Pallet Changer Accessories

In addition to setting the industry standard in quality pallet changers, MIDACO produces a wide range of products to maximize the potential its systems can bring to your machining floor.

Tool Shelf for Automatic Pallet Changer

Splash Guard Shield for CNC Chip and Coolant on Automatic Pallet Changer

Pneumatic & Vacuum Workholding Management

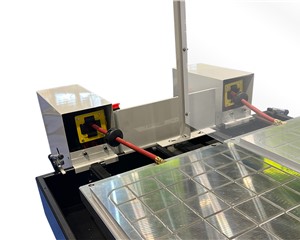

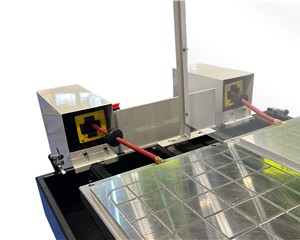

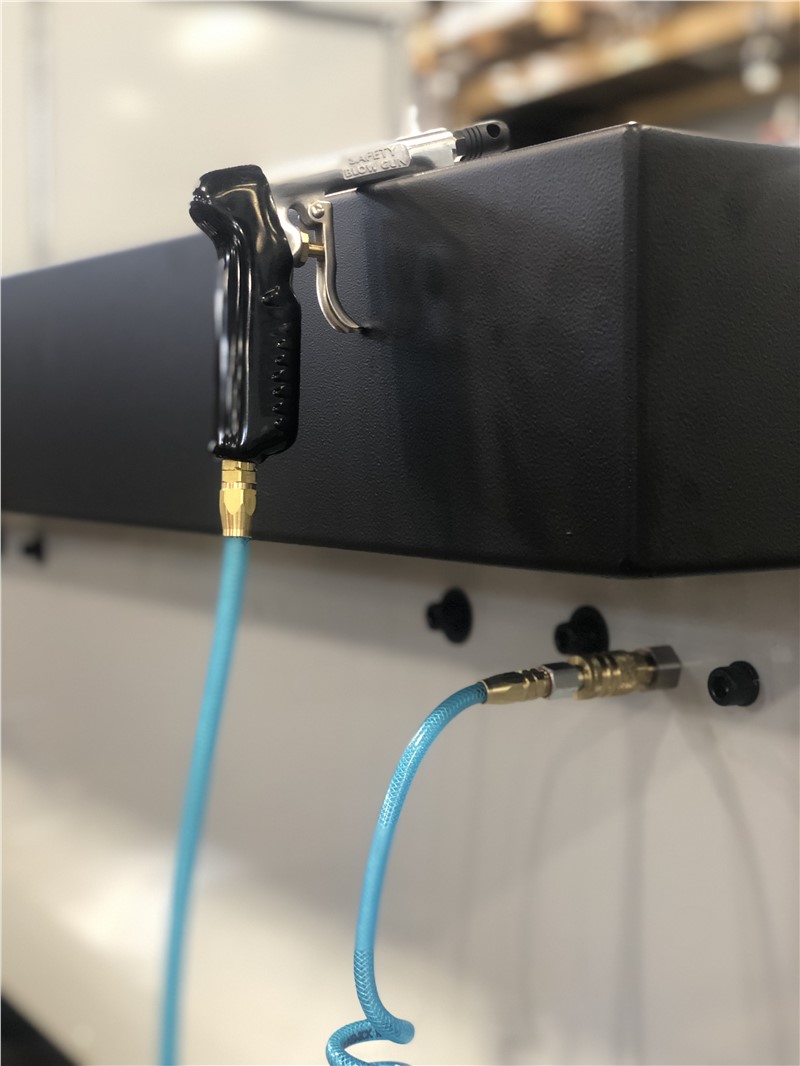

Blow-off Nozzle Kit for CNC Chip and Coolant Cleaning

Each kit includes a set of two lever-action blow-off nozzles mounted on both the left and right side of the pallet changer and is fitted with a pilot return valve, fittings and a quick-disconnect system. Take advantage of uninterrupted air-flow at a wide range with the standard ¼" diameter, 25-foot reinforced coil line integrated directly into the existing air line of the pallet changer it is installed on.

MIDACO can eliminate the hassle of installation by integrating the kit into a new MIDACO Automatic Pallet Changer in the factory, but our innovative design allows for an easy install process on an existing system as well.

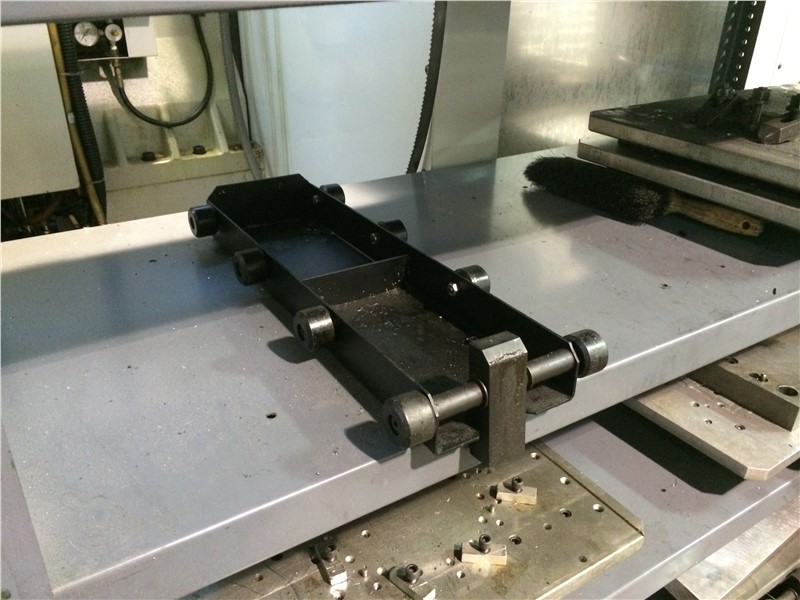

Shelf Rail Kit for Pallet Storage

When you’re done cleaning up the machining centers and the pieces MIDACO has made easier to produce, MIDACO’s Shelf Rail Kits (A16SD, A30SD & A40SD and AS50SD) can fit a variety of pallets and pallet sizes and are used with a customer-supplied storage rack to make storage and transfer easier than ever.The kits provide convenient dedicated pallet and receiver storage with easy transfer along rollers and are available for A16SD, A30SD, A40SD and AS50SD pallets.

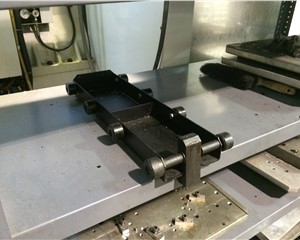

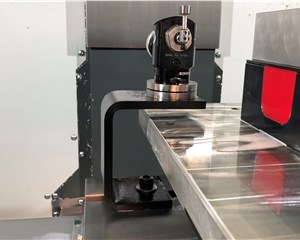

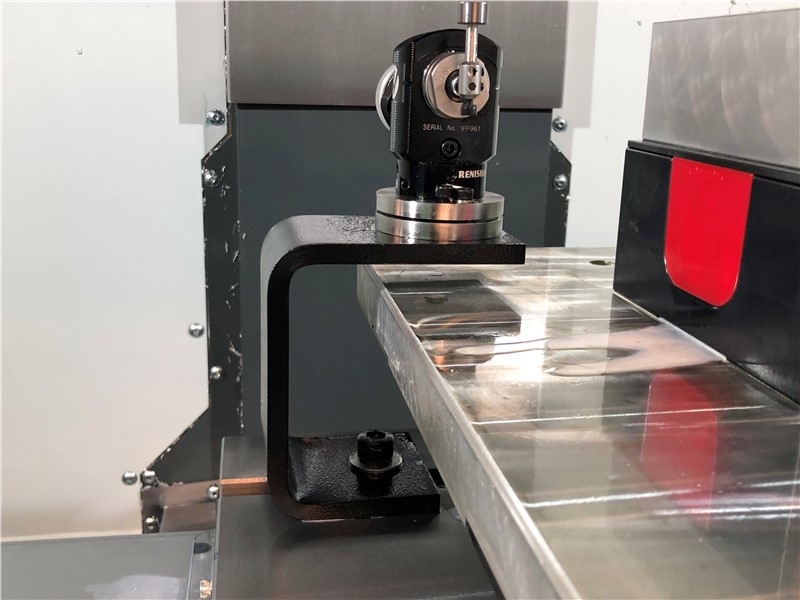

Touch Probe Mounting Kit

MIDACO also makes it easier to integrate a touch probe into your machining process with its Touch Probe Mounting Kit, which includes a C or Z shape bracket for mounting a touch probe in order to accommodate the pallet changer receiver and pallet mounted on your vertical machining center table.

Laser Adjustment Tool for Light Curtains

MIDACO's Laser Adjustment Tool is the solution for maintaining accurate laser beam alignments for Light Curtain guarding on Automatic Pallet Changer Systems.CNC Chip Fans

All of this comes with our guarantee to consistently strive

for quality in excellence in product design, manufacturing and service to our

worldwide customers and have cemented our place as leaders in the industry due

to our premier products and unmatched customer service.