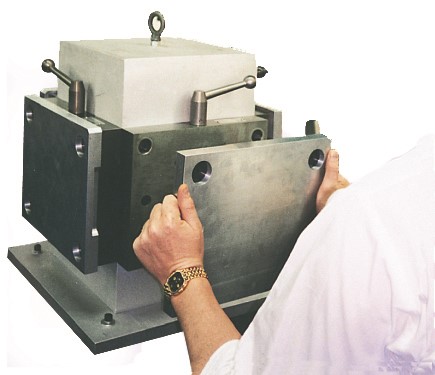

MPS 31 Micro Pallet System

MIDACO's Micro Pallet System allows operators to manually change pallets in seconds for maximum productivity. Adapts to any horizontal and vertical machining center, tapping, drilling, milling, CMM and EDM machines.

MPS31 features:

- Easy flip handle precisely locks pallet into low profile cast iron receiver.

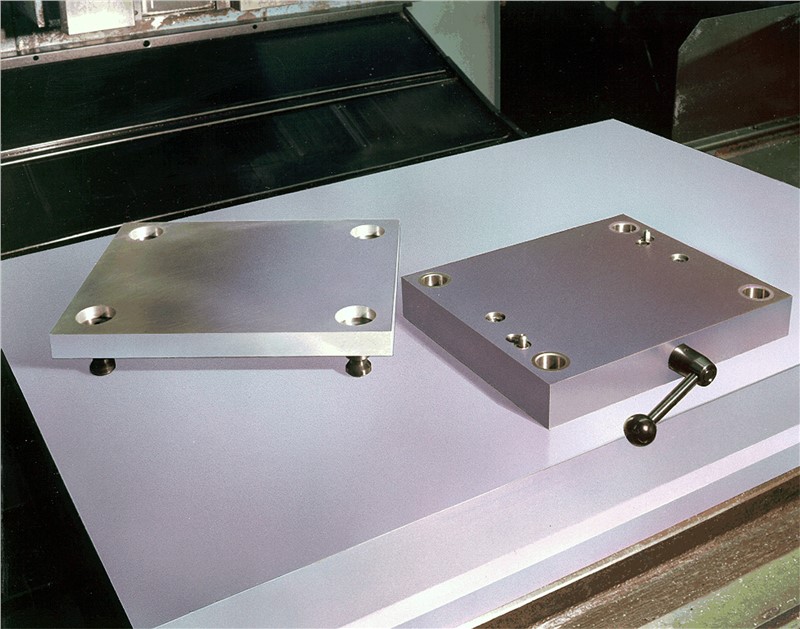

- 2 - 12.75" x 10.5" x 1" (323.9mm x 266.7mm x 25.4mm) Front Load Cast Aluminum Pallets.

- 8 - Retention studs.

- Utilizes a mechanical clamping system.

- Does not require any air/hydraulic or power lines.

- Pallet exchanges done in Seconds, with +/- .0001" (.0025 mm) repeatability.

- Easily transfer from machine tool to inspection.

The

History of MIDACO’s FIRST Pallet Changer

MIDACO CORPORATION started business in 1969 with a

handful of employees as a job shop providing quality metal cutting services for

a variety of manufacturers in their area. While looking for a way to increase in-house

production and reduce unnecessary downtime due to part loading and unloading at

their machining centers, they discovered that what they actually needed really

wasn’t available.

“Our quest was for an efficient, cost-effective pallet exchange system that we could easy integrate onto our existing equipment,” says Mike Caley, Jr., MIDACO’s Vice President of Manufacturing. “Although pallet changers were available as built-in options on new machines, we wanted to find a system that we could easily move from machine to machine, depending on the jobs we were running.”

They decided to design and build their own productivity solution that matched their requirements.

“Quality, versatility and affordability were the keys

to the success of our pallet shuttle systems,” states Mike Cayley, Sr.,

President. “Being a job shop gave us the

perfect insight into the manufacturing needs of others, and that has also paid

off in optimum productivity within our own facility.”

“Quality, versatility and affordability were the keys

to the success of our pallet shuttle systems,” states Mike Cayley, Sr.,

President. “Being a job shop gave us the

perfect insight into the manufacturing needs of others, and that has also paid

off in optimum productivity within our own facility.”

This simple, yet durable design soon became the foundation for a full line of affordable CNC Pallet Changer Systems.

Today, MIDACO still manufactures the hand held MPS-31 among their full line of Manual and Automatic Pallet Changers and offers systems for any New or Existing VMC with pallet sizes ranging from 12” x 10.5” (323.9mm x 266.7mm) up to “190 x72” (4826mm x 1829mm).

Additionally MIDACO has developed AutoDoor Openers and Robot Access Doors, and offers other time saving accessories such as Industrial CNC Vacuums, CNC Chip Cleaning Fans and Grinder Guard & Grit-Grabber Systems for added machine shop efficiency. Today, as a leader in its field, MIDACO supplies job shops, manufacturers, distributors and OEM’s throughout the world.