Now that the International Manufacturing Technology Show (IMTS) 2024 has come to a close, MIDACO Corporation is proud to reflect on our successful participation at one of the world's largest manufacturing technology trade shows. We showcased our productivity boosting products that maximize CNC machine efficiency and spindle utilization, providing manufacturing professionals with the tools to revolutionize their operations.

Recap: MIDACO at IMTS

Throughout IMTS 2024, attendees visited us at Booth #339347 in the South Hall at McCormick Place in Chicago, where our experts demonstrated the latest innovations in CNC productivity solutions. We introduced numerous products aimed at reducing downtime, improving workflow, and enhancing safety, all designed to boost machine shop productivity.

For those who couldn’t attend or want a deeper look, here's a detailed overview of our featured products:

Revolutionizing CNC Efficiency: Our Product Line

At MIDACO, we specialize in developing cutting-edge solutions that streamline operations and maximize spindle utilization on CNC machines. Our range of products includes:

Automatic Pallet Changers: Our automatic pallet changers are engineered to eliminate spindle idle time by enabling the operator to load parts outside the machine while it cuts, making transitions between operations seamless. Available for any brand or model of Vertical Machining Center (VMC), our 2-pallet systems come in sizes ranging from 22” x 14” (558.8mm x 355.6mm) to 190” x 72” (4826mm x 1829mm), designed to handle a wide variety of workloads.

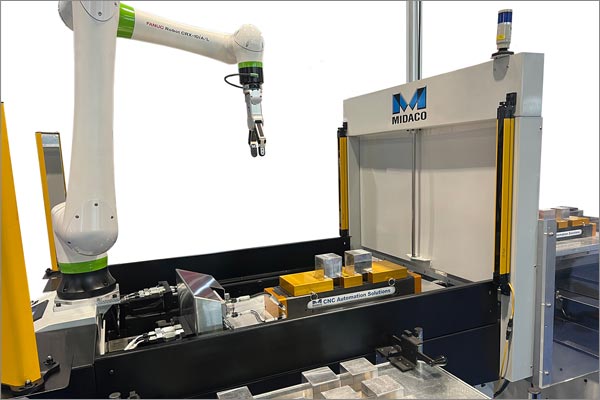

Automatic 4-Pallet Pools for VMCs: Our 4-pallet pool systems expand productivity even further by enabling hours of unattended machining, ideal for lights-out operations. Offering pallet sizes from 28” x 15” (711.2mm x 381mm) to 50” x 24” (1270mm x 609.6mm), these systems are perfect for extended run times, minimizing operator intervention. (shown with Midaco Trunnion System on all 4 pallets)

Trunnion Systems: Enhance 4th-axis productivity by transforming your vertical machining center into a horizontal machining center without the hassle of cable management. This system includes a 4th axis actuator assembly, and two trunnions mounted on MIDACO’s Automatic Pallet Changer, or 4 trunnions on the Automatic Rotary 4-Pallet Pool, enabling seamless integration with your 4th-axis rotary indexer (not included). Designed for versatility, with one trunnion on each pallet, you gain access to multiple machining setups using a single rotary indexer.

Manual Pallet Changers: For smaller machine shops or operations with limited floor space, our front-loading manual pallet changers provide the same part-transfer efficiency benefits with simple, user-friendly manual operation. With sizes ranging from 16” x 14” (406.4mm x 355.6mm) to 60” x 25” (1524mm x 635mm), these economical systems offer significant flexibility for a range of applications.

CNC AutoDoor Systems: Designed to improve safety and cycle times, our CNC AutoDoor systems automatically open and close machine doors, reducing wear on your equipment and operators. For shops integrating automation, our Robot Access Doors provide an additional entry point for robots and cobots, ensuring that machining processes remain uninterrupted.

Industrial Vacuums: MIDACO's industrial vacuums are designed to remove oil, liquids, and metal chips, efficiently maintaining your machine tools. With flow inversion systems, these vacuums reintegrate or dispose of lubricants and coolants, while an interior micro-perforated basket with an additional 150-micron PPL filter ensures proper separation of solids and liquids for streamlined operations.

CNC Productivity Accessories: We also offer a range of accessories to complement your existing pallet changer systems. From Robot/Cobot Mounts and Hydraulic Docking Systems for automated fixtures, to Hose Reels for pneumatic workholding and vacuum tables, our solutions can extend the versatility and efficiency of your VMC. Chip management and pallet storage solutions are also available to optimize your shop’s overall workflow.

MIDACO Corporation is committed to helping you unlock the future of CNC productivity. Explore how our innovative products can make a lasting impact on your operations!

Couldn't Attend IMTS 2024? Learn More with MIDACO!

If you missed us at IMTS 2024, don't worry! MIDACO continues to be a leader in CNC productivity solutions, and we’re ready to help you elevate your operations. Whether it's through automated pallet changers, manual systems, or productivity accessories, we have the tools you need to enhance efficiency, reduce downtime, and improve safety in your machine shop!