Combine Robots/Cobots

with a MIDACO to Maximize Machining Time

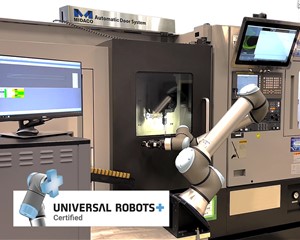

Critical labor shortages call for creative automation ideas such as adding collaborative robots to increase unattended machining. Take your machining to the next level with a variety of MIDACO's “Robot Ready” solutions that take the complexity out of automated CNC machine tending.

Why Automate?

Even a simple 10-15 second delay caused by the cobot adjusting its position to open and close a CNC door in between cycles and readjusting again to reach the part can lead to a significant amount of machining down time over the course of a high production job. Lost time means lost money.

Keep the spindle running

Automating the machining center with a "Robot Ready" Pallet Changer or MIDACO's AutoDoor System (a Universal Robots UR+ Certified product with UR Cap) combined with a Robot/Cobot helps achieve that goal while reducing wear on the cobot by eliminating unnecessary repetitive tasks and improving ergonomics for a human operator, as well.

For more information

Call or complete our online contact form today.