Maximizing VMC Productivity with Midaco Automatic Pallet Changers

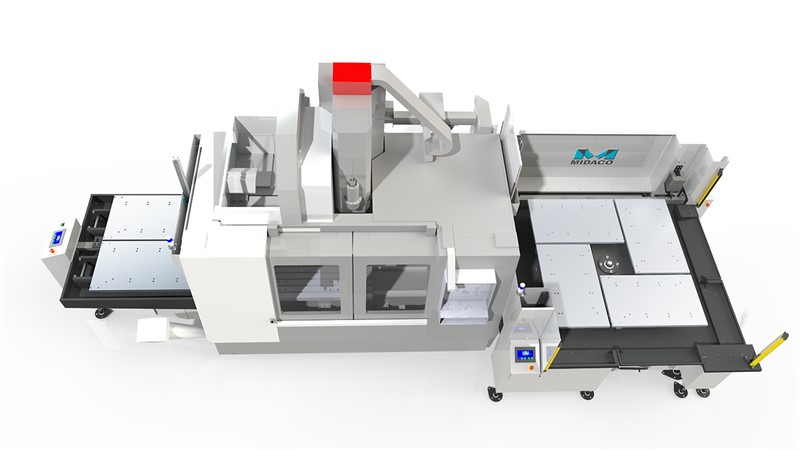

How many pallets do you need to maximize your VMC productivity? Is it two, four, maybe six? If that's not enough, why not consider eight pallets with a "dual" 4-pallet changer.

MIDACO's Automatic Pallet Changers are here to revolutionize the way you approach machining productivity. Whether you're working with a new VMC or your trusty existing one, these pallet changers can be your ticket to unparalleled efficiency.

The Power of Automation

Imagine being able to change parts on the pallets outside of the VMC while the spindle is still cutting, then walking away while the pallets swap out automatically once the cycle is complete. That's the kind of productivity boost MIDACO's pallet changers bring to the table. They increase efficiency by eliminating spindle idle time, ensuring that your machine is in constant motion.

By combining automatic pallet changer models on one machining center you can have 4, 6 or even 8 pallets with multiple jobs set-up at the ready. It's like having the power of two milling machines in one.

- 2-pallet systems* from 22"x15" (559x381mm) to 150"x32" (3810x787mm) and up to 8,000 lb (3,632kg) capacity per pallet.

- 4-pallet systems* from 26”x15” (711x381mm) to 50"x24" (1270x610mm) and up to 2,000 lb (908kg) capacity per pallet.

Pallets transfer with +/-0.0001" (0.0025mm) repeatability

Seamless Integration

One of the most significant advantages of MIDACO's pallet changers is their ease of use. There's zero learning curve, and you can take the complexity out of automation because the pallet changer is integrated with your VMC via M-Codes. Just load and reload multiple jobs on different fixtures on separate pallets while the machine is cutting away and the pallets transfer automatically in-between cycles with +/-0.0001" (0.0025mm) repeatability

Maximizing table space and efficiency inside your mill is essential, and MIDACO pallet changers make it possible to use the entirety of your VMC table's real-estate by mounting your fixtures on dedicated pallets. Transfer an entire table of parts in seconds on one pallet and reload alternate pallets while the spindle is cutting. It's a seamless process that keeps your VMC running and profitable.

Go Large!

For those operating large Bridge Mills we offer Large Dual System Automatic Pallet Changers with pallet sizes reaching an impressive 190"x72" (4826x1829mm) and up to 32,000 lb (14,528 kg) capacity per pallet {with part weight evenly distributed}. Without any overhead obstruction, these automated "dual" shuttles — each with one large pallet on either side of your VCM — are a solution that ensures seamless and efficient heavy part changes with your crane or gantry loader outside the mill while the spindle is cutting.

Automatic Pallet Changers for large Bridge Mills and Vertical Machining Centers which do not move in Y-Axis

No Y-Axis? No Problem

The Bottom Line: Is Your Spindle Running?

MIDACO's Automatic Pallet Changers are not "rocket science", but they are the key to unlocking your VMC's true potential. It's a No-Brainer — If you want to be more efficient, make greater profits, and keep that spindle running, it's time to consider how MIDACO can transform your machining operations. Don't let idle time hold you back — get MORE out of your machining center with MIDACO.

Customer Testimonials: See what MIDACO pallet changer users have to say

For more information on MIDACO Pallet Changers

Call or complete our online contact form today

Unlock Your Shop's Potential with a Variety of MIDACO's Productivity Solutions

Industrial vacuums ranging from 100 to 500 liter tank capacity, deliver powerful performance. Wet vacuums feature CNC chip filtration and flow reversal for liquid reintegration or easy disposal, and dry vacuums are tailored for demanding clean-up tasks in machine shops and woodworking or contractor environments.

Achieve greater efficiency by automating door operations between cutting cycles. This ergonomic solution saves valuable time and wear, eliminating the need for manual door handling by operators or robots.

Retrofitting these automated door panels to any enclosed CNC milling or turning center provides an alternate access — from the side or top like a sunroof — for robot tending applications or overhead crane and gantry loading.

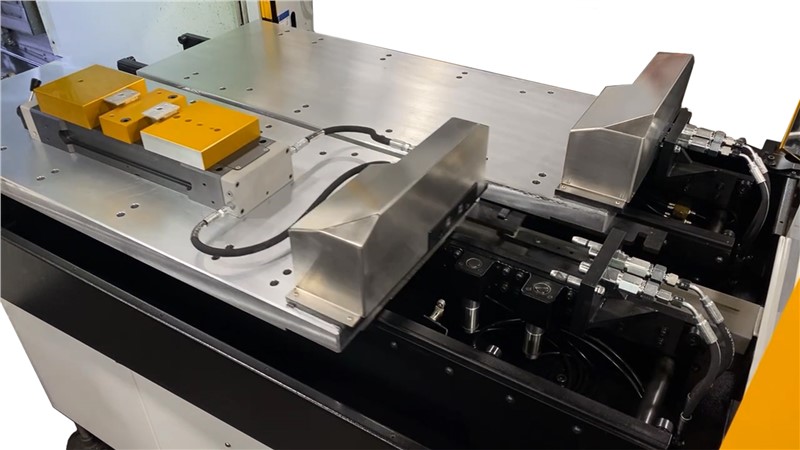

Transform your vertical mill into a versatile horizontal machining powerhouse with a Trunnion System on Automatic Pallet Changers. Only ONE rotary indexer (not included) is needed inside the VMC to run both pallets. No cable management required.

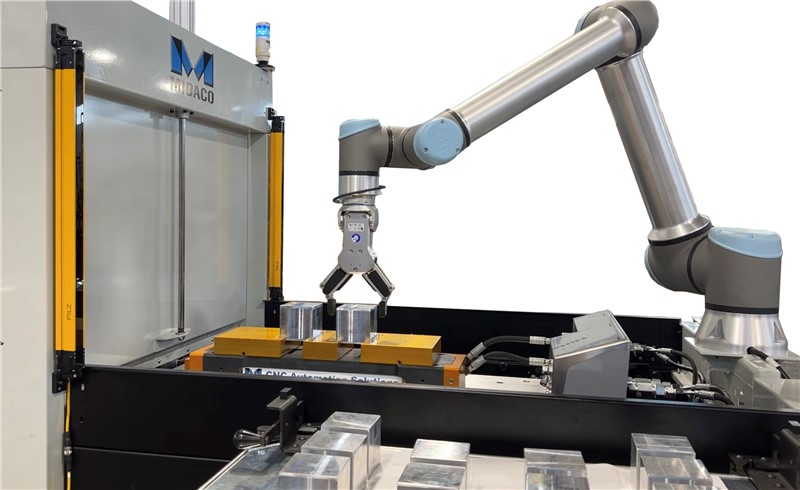

"Robot/Cobot Ready" CNC Machine Tending

Take your machining to the next level with a variety of MIDACO's “Robot/Cobot Ready” solutions that take the complexity out of automated CNC machine tending.

Hydraulic Docking System for Automated Fixtures

With the Hydraulic Docking System on a MIDACO Automatic Pallet Changer, automated fixtures and vises are clamped and unclamped on the pallet and stay charged in the machining center without needing hoses. Ideal for robot loading.

From Chip Fans, Chip Shields to Tool Shelves, Blow-Off Nozzles, Touch Probe Mounts, and Pallet Storage Racks, our versatile range of accessories enhance customization for your Pallet Changer.

Grinder Shield with LED light and Vacuum Pedestal Cabinet

The GRINDER GUARD® and GRIT-GRABBER™ Dust collection System is designed for use with virtually all pedestal grinders and buffers. Minimize the hazards and debris associated with bench and pedestal grinding jobs with this LED illuminated safety station and vacuum stand in your shop.

Comments