Showing a NEW MIDACO A4020SD Automatic Pallet Changer on a 25-year-old HAAS VF-3 Vertical Maching Center

A question we hear quite often is, “Does your Pallet Changer work on older machines?” - YES!

After seeing how much value MIDACO Pallet Changers brought to their new VMCs, job shops have been choosing to add pallet changers on their older machines, too — such as this 25-year-old HAAS VF-3.

Advantages of Automating Older Machinery

If you don’t have room in your shop or in your budget for another Vertical Machining Center, scale up with minimal disruption and experience almost zero idle time when running. It’s worth visualizing the benefits of your older VMC with a MIDACO, which can increase an existing machine’s productivity by an additional 50-70%.

Get MORE Out of Your Existing VMC

An Automatic Pallet Changer on your existing VMC provides the ability to set up multiple jobs without losing cutting time. Load parts on the pallet outside of the machining center while it's cutting, instead of loading parts directly onto the VMC table. Even with lower quantity batch runs, a different job can be loaded onto each pallet and will automatically transfer unattended in seconds once each cycle is complete. The operator is free to work on other tasks and return to load another batch of parts while the alternate pallet is in the machine. The goal is to keep making chips.

See

what other MIDACO customers have to say.

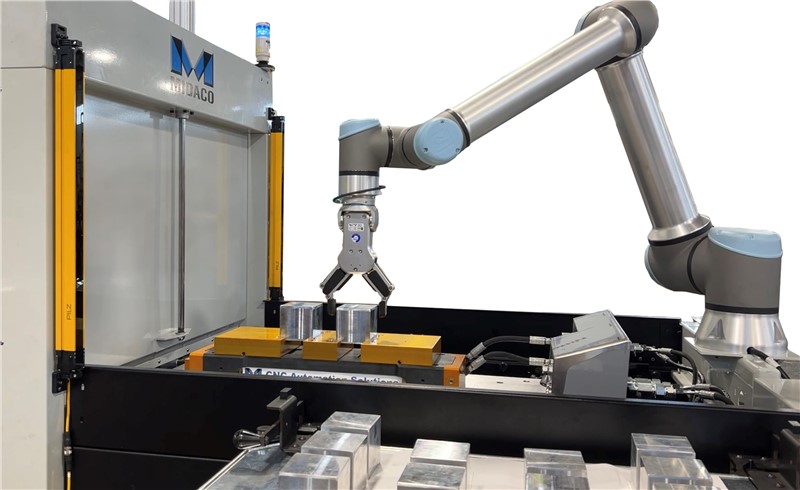

Keep Your Spindle Running With Collaborative Automation

We Are "Robot Ready"

If you’ve considered adding a robot to

your maching process, MIDACO offers a “Robot

Ready” Automatic Pallet Changer designed to take the complexity out of

automated part loading.

For fully collaborative automation on your older VMC, MIDACOs Automatic Pallet Changer is available with a Robot/Cobot mount directly on the shuttle, allowing your cobot to reach parts on a cart or conveyor set up on either side of the machine. Your unattended machining time just depends on how many blanks you’re able to set up.

Automated Part Clamping Without Needing Hoses

Included in the “Robot Ready” package is a Hydraulic Docking System which locks automated fixtures or vises into place as the pallet enters the machining center. Hydraulic vises will stay charged on the pallet while inside the machining center without needing hose management. Once the cycle is complete, the pallet docks back into place, releasing vices automatically allowing the robot to load the next batch.

Available in Pallet sizes from 22"x16" up to 190"x72"

Our automatic systems are compatible with virtually every make and model Vertical Machining Center with XY travel of 22"x16" up to 190"x72". Whether it's five, ten or 25 years old, your high quality VMC is made to last. Get the most out of it with MIDACO Pallet Changers and double its productivity, regardless of its age.

For more information

Call or complete our online contact form today.

Comments