Gaining over 90% Spindle Uptime on VMC with MIDACO Automatic Pallet Changer

Darren Grainger of Hi-Spec Precision Engineering Ltd and Grainger Guitars in the UK speaks with Swarf and Chips about his company's growth with implementing automation solutions.

"Cycle time is just under 45 minutes due to the efficiency of this set up {MIDACO Automatic Pallet Changer on HURCO VM5i}. This job in particular is running in cycle for 9 hours 15 minutes of our 9 1/2 hour shift, which is 98.5% efficient for the available time. Got to admit, we are more than impressed with this setup."

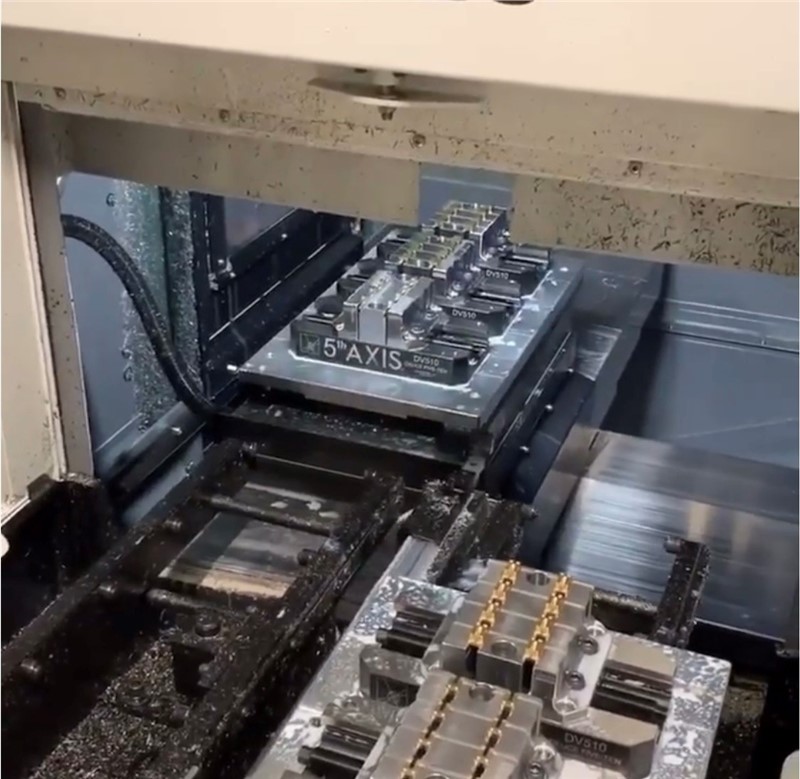

Tell us about your process - This is our MIDACO Pallet Changer. It’s their smallest {Automatic Pallet Changer} model, I believe. It’s bolted onto the side of our HURCO VM5i. We have 2 platens {pallets} within the pallet changer. Each platen {pallet} has 3 vises on. One will be in the machine working; when that’s done it will be pulled out and the other one will automatically go in. So we can load the vises, load the pallets whilst the machine is running keeping spindles turning. On this one in particular we’ve had upwards of 90% {spindle utilization}. I can pick certain jobs where we’ve had 96-97% spindle uptime within our shift. So it’s doing a fantastic job.

Embracing automation to ensure we are ready for the future.

MIDACO Pallet System = CNC Automation = Efficiency = Productivity

Any machine or machine accessory manufacturer will tell you the increases in efficiency and productivity their equipment will bring to your company. It was no different with our MIDACO pallet changer and I expected that we’d see a decent improvement; however, by utilizing multiple 5th Axis Workholding vices along with the MIDACO pallet changer we’re experiencing some extremely impressive run time efficiencies.

Running in cycle for 9.25 hours of our 9.5 hour shift... which is 98.5% efficient

- Darren Grainger, Director

Hi-Spec Precision Engineering, Ltd. email: info@hi-speceng.co.uk

Grainger Guitars email: info@graingerguitars.com

Video and image credits:

Hi-Spec Precision Engineering Ltd

Grainger Guitars

Swarf and Chips

Hyfore (UK Distributor)

Unit 3, 67 Blackhorse Road

Longford, Coventry

England CV6 6DP

Tel : 024 7699 3153

Comments