In the world of industrial automation you need to stay competitive.

"The idea is to keep the machine spindle running."

"Double the realestate of your machine tool."

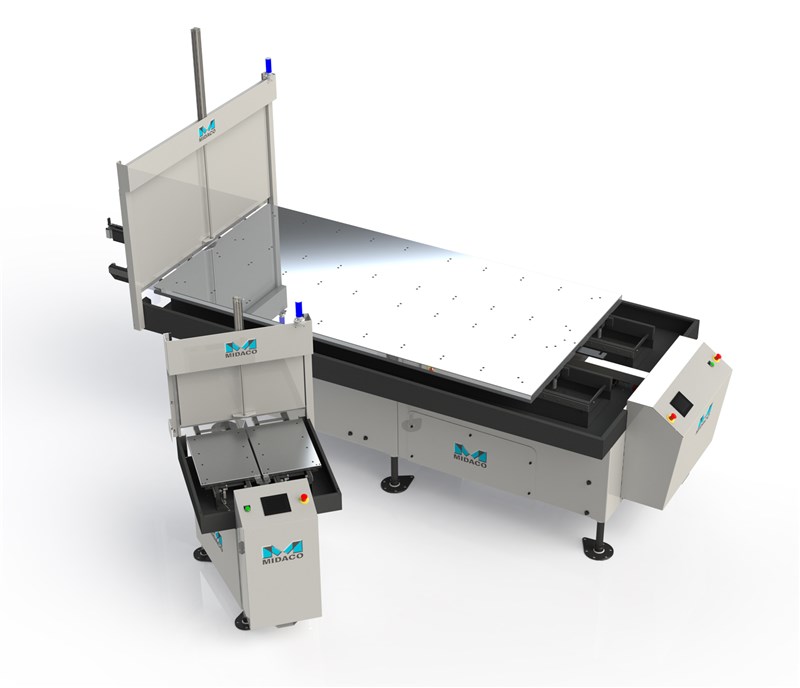

Shown:

- Automatic A40SD standard pallet changer with 1 shuttle and 2 aluminum pallets on Okuma Genos M560V.

- Automatic A160SD Single Dual pallet changer (left side mount shown) with 2 shuttles, 2 aluminum pallets and Light Curtain Guarding option on HMG bridge mill.

- Manual M30FL standard shuttle and 2 aluminum pallets on Samsung MCV50.

Comments