How long is your spindle idle while changing parts on a Bridge Mill?

...an hour ...two hours?

We can get it running in MINUTES!

Idle machine time means slow production and lost profit per each machine owned. MIDACO pallet changers are a simple solution to eliminate unnecessary spindle downtime and rescue lost profit on large as well as small and mid-size machining centers. A pallet changer allows you to load your part onto a shuttle outside the machine tool WHILE your VMC is cutting, then change out your large part in MINUTES.

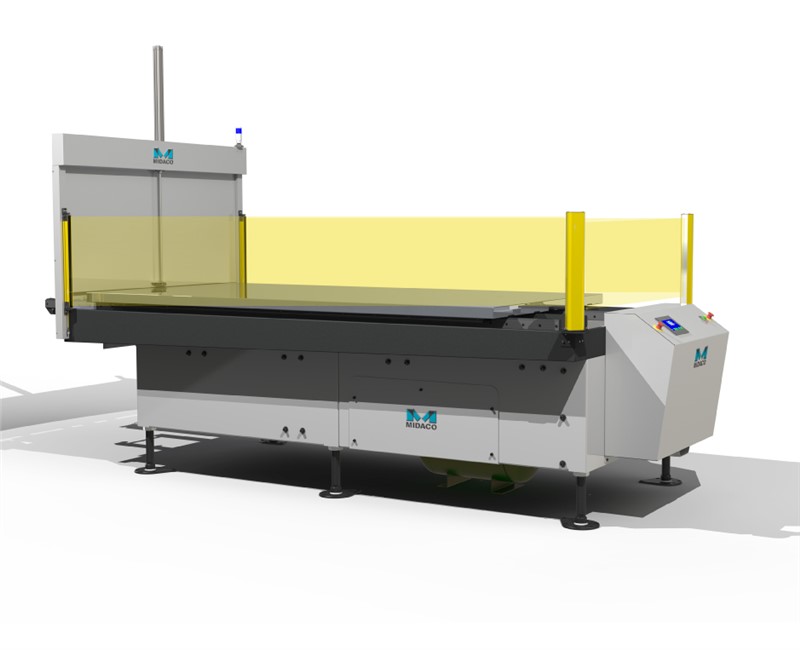

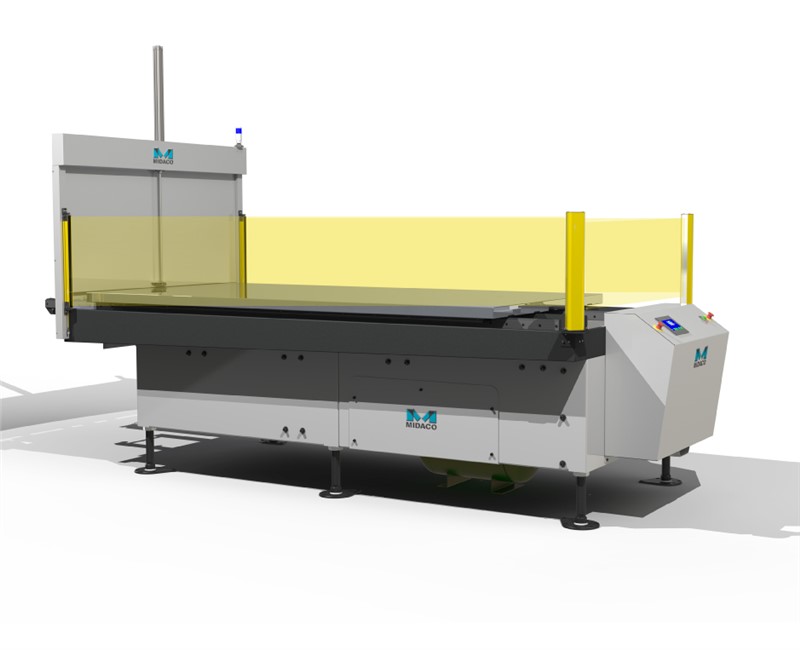

Large (and small) Automatic Pallet Changer models offer a Light Curtain Guarding option with light emitters, mirrors and sensors.

Automatic Pallet Changers are servo driven and are designed to offer a fast pallet change time along with these additional benefits:

- Decrease in load time by changing parts outside of the machine tool.

- No overhead obstructions for your crane access.

- Operator is not leaning into or climbing around inside a machine tool to clamp and fixture parts on the VMC table.

- With multiple dedicated pallets you have additional set-ups available for your diverse machining needs.

- Don't allow your machine to sit idle up to 70% of the time. Keep the spindle running!

The Automatic Pallet Changer line offers large capacity machines such as:

- Single Shuttle Systems mounted on the right or left side of a VMC with 2 pallets up to 150” x 31” (3,810mm x 787mm) and 8,000 lb (3,632 kg) load capacity receiver (with parts evenly distributed).

- Dual Shuttle Systems (one mounted on each side of the machine) with a total of 4 pallets up to 150” x 31” (3,810mm x 787mm) and 8,000 lb (3,632 kg) load capacity receiver (with parts evenly distributed).

- Single/Dual Shuttle Systems with a total of 2 pallets for machines that do not move in Y-axis, up to 190” x 88” (4,826mm x 2,235mm) pallet size and 32,000 lb (14,528 kg) load capacity receiver (with parts evenly distributed).

Your VMC can do MORE with MIDACO!

MIDACO offers a full line of Automation Solutions to fit your Machining Centers

- Manual Pallet Changer System

- Pallet sizes from 12.75"x 10.5" (234mm x 267mm) up to 60" x 25" (1,524mm x 635mm)

- Up to 1,000 lb (454 kg) weight capacity (2,000 lb optional upgrade)

- Automatic Pallet Changer System

- Pallet sizes from 22" x 14" (229mm x 356mm) up to 190" x 88" (4,826mm x 2,235mm)

- Up to 32,000 lb (14,528 kg) weight capacity (with parts evenly distributed).

- Automatic Multi-Pallet Changer System for 5-axis machining

- 19 stations each with a 10" (254mm) dia. round pallet

- Trunnion System for 4th Axis machining

- No Cable Management Needed

- Turn your Vertical into a Horizontal

- Automatic Door System

- For single and double doors

- Operator ergonomic benefits

- Ideal for robot loader applications

Comments